Technically Speaking | 4 APRIL 2025

Screw Design

Tech Tips from Our Engineers at Bamberger Amco Polymers

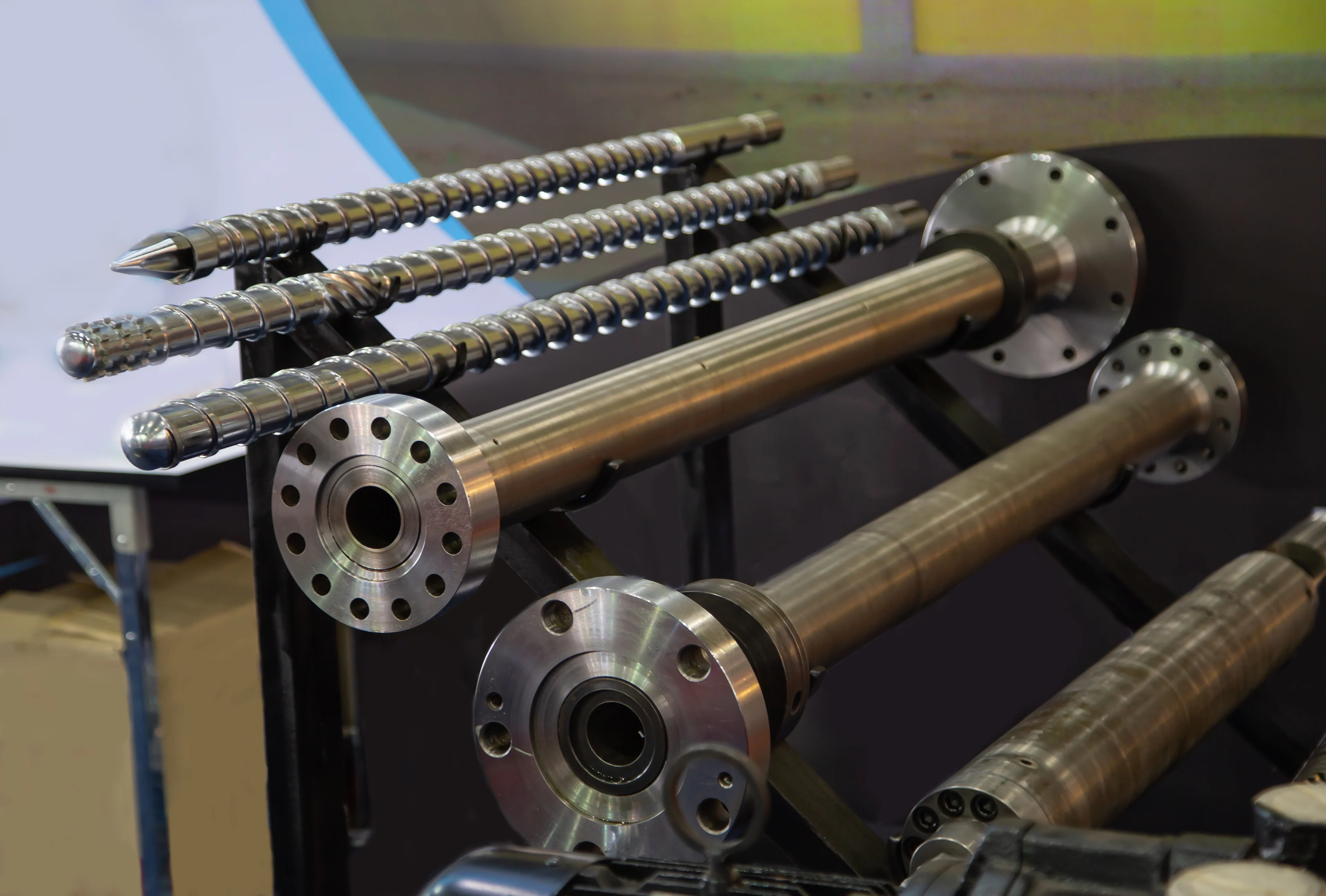

What is an Injection Molding Screw and How Does It Work?

While not all plastic molding approaches rely on a screw, the standard injection molding process uses one to melt, mix, and fill molds with molten material.

Through the application of mechanical friction and heat, a rotating screw compresses plastic pellets, melts them, mixes in additives, and “meters” the material, collecting it at one end in preparation for injection. Finally, the screw moves forward like a piston, injecting molten plastic into a mold cavity at a specific speed and pressure.

Selecting the Best Screw Design for Your Resin

Using the proper screw design will result in consistent melt quality, mold cycle efficiency, and optimal part performance. The right design will control shear, prevent material degradation, and maximize homogeneity — which is especially important for applications involving engineering resins, filled compounds, or recycled materials.

Why Screw Design Matters in Injection Molding & Extrusion

An injection molding screw directly affects:

- Melt homogeneity and temperature control

- Throughput and cycle time

- Material degradation risks

- Color dispersion and additive distribution

Important Variables in Screw Design

To choose the correct screw design for a resin (or resins), we need to understand metering screw design factors and their effects on material processing.

There are five main variables that determine how a screw turns solid resin into a melt. Adjusting them can yield a range of results. They are:

- Profile

- Channel Depth

- Compression Ratio

- Length/Diameter (L/D)

- Helix Angle

When customers purchase material through us, Bamberger Amco Polymers shares all injection molding screw guidelines that our supplier partners can provide. This helps our customers know exactly what kind of screw will best suit their project.

Screw Profile

The standard screw profile is divided into three zones:

- Feed Zone: Conveys solid pellets toward the transition zone.

- Transition Zone: Initiates melting via compression and shear.

- Metering Zone: Finalizes melting and delivers uniform melt to the mold or die.

A modified screw profile may be required for shear-sensitive materials, high-performance resins, or multi-material blends.

Channel Depth

The feed and transition zone channel depths are related to the screw's compression ratio and profile.

The meter zone's channel depth depends on the type of resin being processed.

- Deeper channels: Higher throughput, lower shear

- Shallower channels: Higher shear, better mixing

Channel depth gradually decreases from feed to metering zone. It plays a major role in shear intensity and material output.

Compression Ratio

The ratio of the screw's feed zone channel depth to the meter zone channel depth is called the compression ratio. It typically ranges from 1.5:1 to 4.5:1 for most thermoplastic materials.

The compression ratio (feed depth ÷ metering depth) typically falls between:

- 1.5:1 to 2.0:1 – for heat-sensitive or filled materials

- 2.5:1 to 3.0:1 – for general-purpose resins like PP, PE, PS

- 3.5:1 to 4.5:1 – for crystalline materials or high-viscosity resins

Most injection screws classified as "general purpose" have a compression ratio of 2.5:1 to 3.0:1.

Length-to-Diameter Ratio (L/D)

This ratio calculation is made by dividing the flighted length of the screw by its nominal diameter.

Helix Angle

The angle of a screw flight measured relative to a plane that's perpendicular to its centerline. The helix angle affects:

- Material conveying rate: Extruded material, which is often measured in lbs/hr.

- Residence time: How long resin stays in contact with the screw. For commodity resins, this presents less of a concern, but engineered thermoplastics (ETPs) may degrade if residence time is too high.

- Shear intensity: This refers to forces that cause layers of molten plastic to slide against each other during flow. High material viscosity, paired with a high material conveying rate, causes increased sheer stresses in a molded part.

Standard screws use a square pitch (~17.7° helix angle), but variations may be necessary for specialized applications. The helix angle isn't often altered from the standard "square" pitch, since such changes can have a significant impact on processing.

Optimizing Screw Design for Better Polymer Processing

A tailored screw design ensures better processing stability, melt quality, and product consistency. Whether you're molding high-clarity polycarbonate, extruding fiber-filled polypropylene, or processing PCR blends, understanding how each variable impacts performance is key.

Need help selecting the best screw for your resin? Our technical team, which works directly with processors and OEMs, is ready to help!

Featured Expert: David Katz

David is a renowned Technical Service Engineer with over 30 years of industry experience.

As a customer advocate, he supports our sales & marketing efforts through his expertise in material selection, conceptual design, design review, injection molding, extrusion processing, blow molding, troubleshooting, tooling review, and scientific molding education.

Technically Speaking: Tips & Material Insights

Technically Speaking is a content series empowering product designers, molders, and processors with practical knowledge and real-world insights. These tips are drawn from decades of experience in materials science and application development to help you solve problems faster and smarter. With a diverse portfolio and one of the most knowledgeable tech teams in the industry, we help our customers overcome challenges and bring better products to market.

If you’re unsure which material meets your product requirements, let our technical team guide you through material selection and regulatory compliance.

Disclaimer: The information provided in this post is intended solely for general guidance. Outcomes vary based on individual circumstances, and Bamberger Amco Polymers “BAP", "BA Polymers” does not ensure a specific result. Clients shall use their own independent skills and expertise when testing any application of technical support. Bamberger Amco Polymers is not responsible and will not be liable for any discrepancies between expected and actual outcomes. Bamberger Amco Polymers DISCLAIMS ALL WARRANTIES, WHETHER EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF MERCHANTABILITY OR FITNESS OF A PRODUCT FOR A PARTICULAR PURPOSE.