Technically Speaking | 15 OCT 2025

Polymer Films Explained

Tech Tips from Our Engineers at Bamberger Amco Polymers

What Is a Polymer Film?

Simply put, a film is a thin layer of plastic, formed into products like bags, poly-mailers, liners, wraps, and flexible barriers. A film’s thickness, usually measured in mils (1/1000 of an inch), needs to strike a balance between performance, processability, and cost.

Because every polymer film application is highly specialized, distributors need to offer a wide range of materials and grades to meet customer demand.

Are There Different Kinds of Polymer Films?

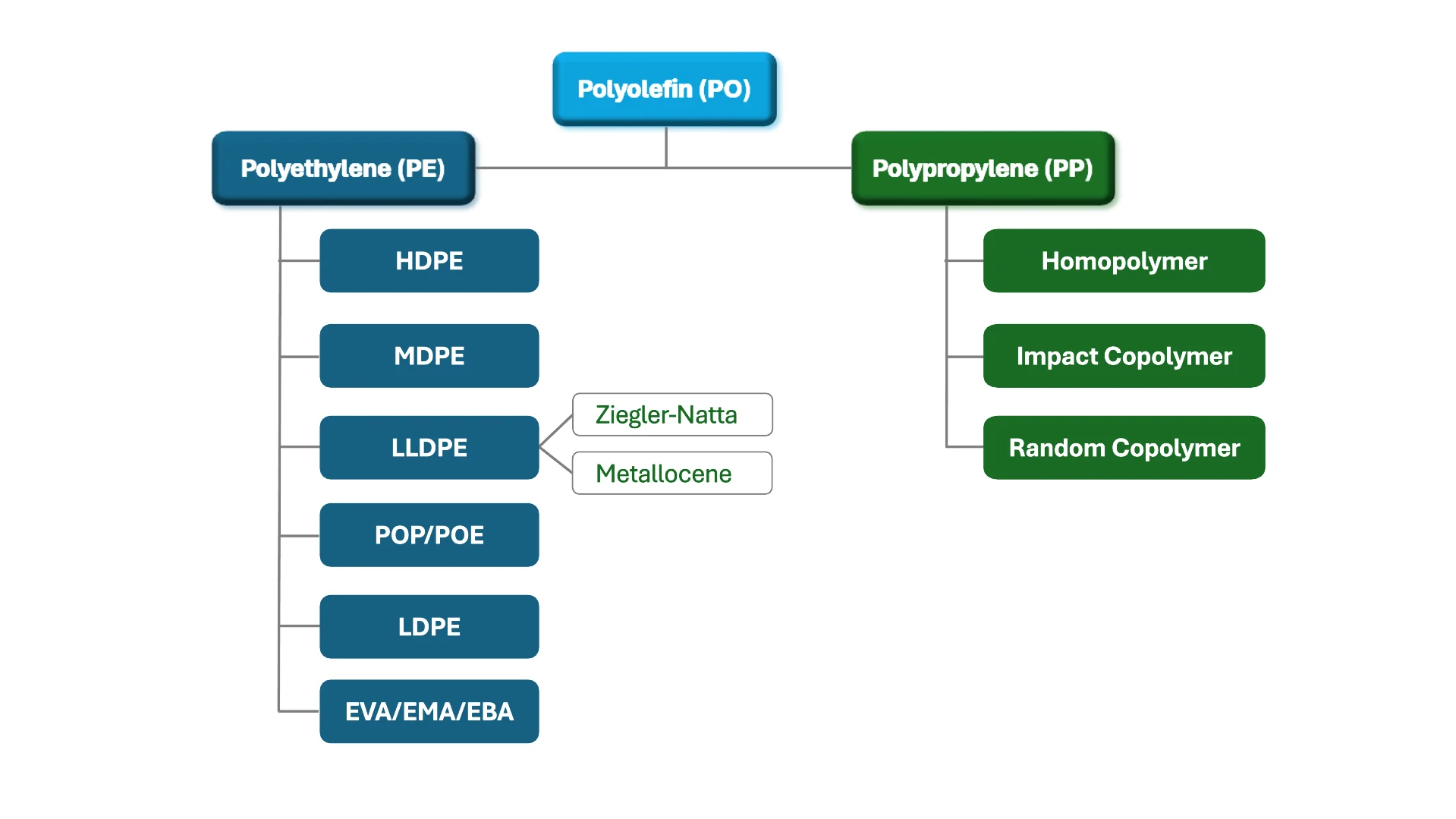

When it comes to polymers used in film applications, polypropylene (PP) and polyethylene (PE) are by far the most common choices for “functional” layers. Both of these material families are polyolefins – materials with excellent properties like chemical resistance, ductility, and a broad range of commercial uses.

The chart below was provided by our resident film expert, Raghu Narumanchi.

PP and PE are often paired with “barrier layers” made of nylon, Ethylene vinyl Alcohol (EVA), or other inorganic, oxide-coated materials that help protect the contents of the resulting container from oxygen and moisture. To adhere PP and PE better to the barrier layer, specialized “tie layers” are also used. When all these resins are “sandwiched” into a single product coming out of a die, the process is called co-extrusion.

What Processing Methods are Used for Films?

The two most common processing methods for polymer films are blown film, which pulls molten resin upward, creating a “tube” shape, and cast film, which creates a flat “curtain” of film that’s usually collected on a roll.

In each method, Melt Index (MI) is an important factor to consider; the lower the MI, the better the film’s properties (generally speaking), but the more difficult it is to process, due to the high viscosity of the melted plastic. Blow molding works well with a low MI, usually between 0.1 and 2. Cast film MI is often between 2 and 5.

Picking the Right Polymer Film.

When deciding on a material, thickness, and number of layers for your polymer film application, consider the following:

• Will your film need to stretch or elongate as part of normal use?

• How resistant does your product need to be to punctures or tears?

• Will your film need to withstand very cold or hot temperatures?

• Should your film’s seals and/or barrier layers keep out oxygen, moisture, or odors?

• Are aesthetics, like clarity or translucency, important?

Our sales and technical support reps will ask questions like these to understand what materials to recommend. Leaning on the experience we’ve gained by working closely with producers, converters, and end-users, we’ll develop and deliver tailored film solutions that satisfy regulations, performance requirements, and your unique design specifications.

Do You Offer Sustainable Film Solutions?

We’re continually developing new sustainable film solutions. The right options for you may include:

• Down-gauging to make your product with less material – often by selecting a different resin with similar properties.

• Mono-material designs, which use a single resin type and make recycling easier.

• Post-consumer and post-industrial resins, which can reduce carbon footprint, cost, and meet evolving requirements for consumer products.

• Our biopolymers, compostable compounds, and bio-circular mass balance approaches take advantage of environmentally responsible feedstocks and advanced recycling technologies.

Why Partner With Us?

We’ll align our broad, flexible range of specialty film grade polymers to your specific use-case. Explore functional layers like low-density polyethylene, linear low-density polyethylene, butene, hexene, and metallocene, to name just a few.

Count on our strong supplier partnerships, proactive technical expertise, and our robust supply chain network – which makes multiple transportation services, a nationwide warehouse network, and custom compounding facilities work for you.

Featured Expert: Raghu Narumanchi

A Business Development Manager with 27 years of expertise in films, Raghu’s chemical engineering background has helped him excel in polymer industry roles spanning business technical service, application development, sales management, business development, consultative sales, and technical sales.

Technically Speaking: Tips & Material Insights

Technically Speaking is a content series empowering product designers, molders, and processors with practical knowledge and real-world insights. These tips are drawn from decades of experience in materials science and application development to help you solve problems faster and smarter. With a diverse portfolio and one of the most knowledgeable tech teams in the industry, we help our customers overcome challenges and bring better products to market.

If you’re unsure which material meets your product requirements, let our technical team guide you through material selection and regulatory compliance.

Disclaimer: The information provided in this post is intended solely for general guidance. Outcomes vary based on individual circumstances, and Bamberger Amco Polymers “BAP", "BA Polymers” does not ensure a specific result. Clients shall use their own independent skills and expertise when testing any application of technical support. Bamberger Amco Polymers is not responsible and will not be liable for any discrepancies between expected and actual outcomes. Bamberger Amco Polymers DISCLAIMS ALL WARRANTIES, WHETHER EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF MERCHANTABILITY OR FITNESS OF A PRODUCT FOR A PARTICULAR PURPOSE.